From lone wolf to ecosystem: how digital services are transforming mechanical engineering

From lone wolf to ecosystem: how digital services are transforming mechanical engineering

Rising costs, volatile markets and a growing shortage of skilled workers are forcing the mechanical engineering industry to rethink. Traditional sales and service models are reaching their limits - innovative business models and technological partnerships are needed. The solution can be seen in building new ecosystems in which machine manufacturers, IT service providers and technology providers work together to create new added value.

Content:

- Traditional systems under pressure

- Product-as-a-Service and Pay per use as a response to falling margins

- Predictive maintenance and visual support as value-added services

- Four areas of action for mechanical engineers

- Future ecosystem model: collaboration is key

- Facilitate entry - with modular tools

- Conclusion: Mechanical engineering 2025 - digital, networked, service-oriented

Traditional systems under pressure

The established model of machine sales including maintenance contracts is being critically questioned. This is due to price increases for energy, raw materials, and other materials, as well as additional compliance requirements that reduce margins, declining orders, and economic crises. Many companies are openly talking about the threat of deindustrialization.

According to a DIHK survey, the number of industrial companies considering production restrictions or relocation abroad has risen steadily—from 21 percent in 2022 to approximately 37 percent. However, there are other models that machine manufacturers can rely on.

*The Gabler Business Dictionary explains the term as follows: “At a high level of economic development, industrial production loses relative importance compared to services.”

Product-as-a-Service and Pay per use as a response to falling margins

Possible solutions: Product-as-a-Service (PaaS) or usage-based billing models such as pay-per-use. According to McKinsey & Co., manufacturers who consistently expand their service revenue can increase it by 30–60% in just 3–5 years.

PaaS:

Comprehensive servitization trends such as Product-as-a-Service (PaaS), in which manufacturers of products switch to service-based models, are increasingly dominating the market. PaaS models offer manufacturers the opportunity to enter into long-term leasing agreements (usually 5 years or longer) and build sustainable and stable customer relationships.

“Both manufacturers and customers of product-as-a-service models depend on seamless service operations—a requirement that can be met efficiently and reliably through the consistent digitization of service processes,” explains Rolf Behrens, Managing Director of Bitnamic GmbH.

Even with Product-as-a-Service, the sale of new machines remains an essential part of the business model. To effectively combine both approaches, comprehensive digitization of processes is essential. Traditional, fragmented processes and PDF-based documentation not only slow down internal processes, but also inhibit productivity and revenue growth.

PpU

Machines are no longer sold, but billed per minute of operation or production unit. However, these models are data-intensive and require complete transparency regarding machine usage and condition. This requires a comprehensive IoT infrastructure with sensors, cloud connectivity, and data analysis.

“Manufacturers need real-time data for pay-per-use models. This is the only way to achieve accurate billing and predictive maintenance,” explains Rolf Behrens.

Predictive maintenance and visual support as value-added services

Digital services such as predictive maintenance enable precise prediction of its unique maintenance requirements and thus avoid unplanned downtime. Remote maintenance and visual support also offer tangible benefits: Technicians can be connected worldwide - quickly, efficiently and without having to travel.

“Visual Support is a key tool, especially in view of the shortage of skilled workers,” says Behrens. “It makes it possible to instruct less experienced staff on site with digital instructions or via video call.”

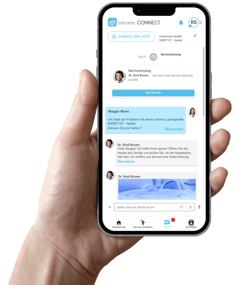

Service Chats inside the Service HUB

Fast and efficient: The service chats in the bitnamic CONNECT Service HUB enable you to submit service requests or provide expert advice in your own language thanks to live translation. Visual support via video call is also included. All processes are automatically transferred to tickets, structured, and tagged. Plus user-friendly, secure, and easy operation. And data sovereignty remains where it belongs: with you.

Fast and efficient: The service chats in the bitnamic CONNECT Service HUB enable you to submit service requests or provide expert advice in your own language thanks to live translation. Visual support via video call is also included. All processes are automatically transferred to tickets, structured, and tagged. Plus user-friendly, secure, and easy operation. And data sovereignty remains where it belongs: with you.

Four areas of action for mechanical engineers

Successful transformation requires a clear digital strategy. Four topics are particularly central to this:

- Data usage: real-time data from machines as the basis for condition monitoring and maintenance planning.

- Customer support: Multi-channel approaches with hotline, ticket system, chat, remote maintenance and visual support.

- Documentation: Digital provision of manuals, checklists and instructions.

- Securing knowledge: Digitally recording specialist knowledge and making it available - also for training new staff.

Future ecosystem model: collaboration is key

A study by Deloitte predicts an increasing integration of machine, service and software in packages. To achieve this, machine manufacturers need to unite their expertise and enter into new partnerships.

“In future, mechanical engineers will no longer be soloists - they will act as coordinators in a network,” says Behrens.

Specialized technology partners take on tasks such as software development, data analysis and cloud operation. Machine builders orchestrate this ecosystem and ensure the compatibility of the systems.

Facilitate entry - with modular tools

One example of such a low-threshold solution is the bitnamic CONNECT software: it can be easily integrated into existing systems, enhanced by APIs and digital documentation hubs. This allows central information to be bundled, processes to be controlled efficiently and services to be digitized.

Conclusion: Mechanical engineering 2025 - digital, networked, service-oriented

The industry is undergoing radical change. Those who want to be successful in the future would be well advised to combine technological developments with new business models. Digital services, predictive maintenance, and networked ecosystems are no longer optional extras—they form the basis for tomorrow's competitiveness.

Please feel free to contact us for more information.

*

https://www.mckinsey.com/capabilities/operations/our-insights/the-industrial-revolution-in-services

accessed on: August 5, 2025