In the following article, you will learn how TECUMA Systems is revolutionising its service processes with our innovative Smart Service solution Visual Support /Remote Maintenance software.

How machine manufacturer TECUMA Systems is cutting costs and increasing customer satisfaction at the same time

TECUMA Systems GmbH, an Osnabrück-based machine manufacturer specialising in packaging technology, slitter rewinders, special machine construction and production optimisation, relies on the latest technologies. Uwe Meyer, Managing Director of TECUMA Systems, explains:

„Direct online access to the system controls and all associated parameters and digitally recordable settings has been part of the standard equipment of a machine for many years. However, if the operator is to be supported directly in handling the complex machine/system, cameras are often used on the main operating units of the machine/system. Or a service technician is sent directly to the customer.”

In addition to the time-consuming maintenance of the systems, complex faults or incorrect settings have so far been followed by time-consuming and costly service processes. For this reason, a project for the international LOXY Group from Norway, with branches in Sweden, Poland, Germany, China and many other countries, has been equipped with a new digital service concept from TECUMA Systems.

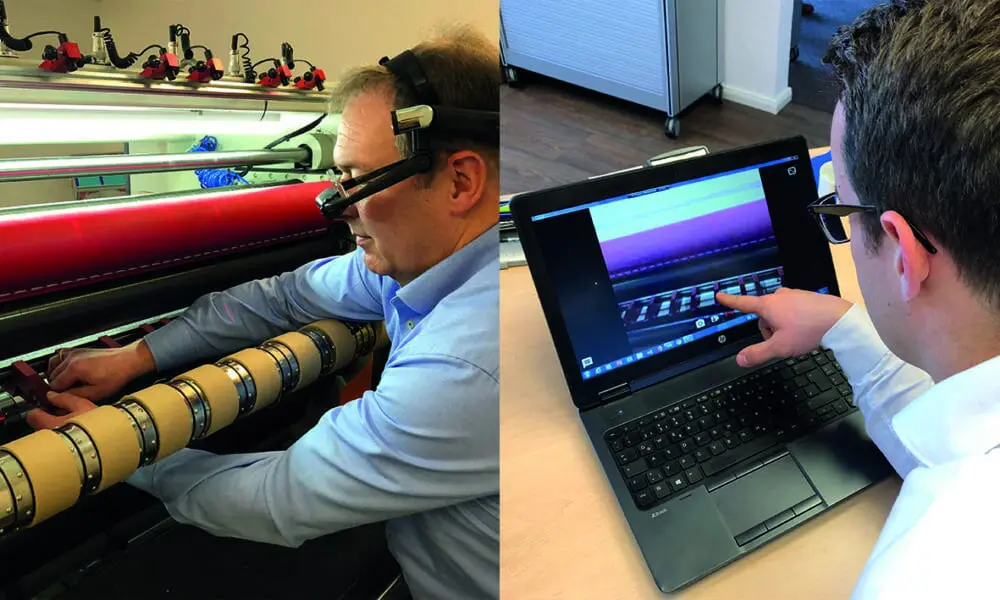

The smart service solution ‘Remote Maintenance’, from software manufacturer Bitnamic GmbH, uses a collaborative platform to enable the machine operator on site to work together with the remote expert through multimedia interaction in real time. Coupled with the head-mounted tablet ‘HMT‑1’, industrial data glasses from RealWear and Barcotec, supporting expertise is made available to the machine operator directly from a distance. The operator can continue to work freely on the machine with both hands.

The fully automated winders specially developed for LOXY for safety materials in the textile sector are installed and maintained with Remote Maintenance Assistance and supported during test series on the machine.

Uwe Meyer also mentions: ‘The elimination of the sometimes very costly dispatch of service technicians, the faster and even more direct support of the operators / maintenance staff at the customer’s site, the possibility that the operator can work directly on the machine with both hands and at the same time call up or record information on the display of the HMT‑1, will make this type of additional service form spread very quickly in the future’.

Strong development partners

BARCOTEC GmbH has been active in the field of automatic identification since 1989 and helps customers to gain market advantages by increasing efficiency with mobile devices and comprehensive solution concepts. The Austrian company is one of the market leaders in this field in the DACH region. Whether barcode scanners, RFID technologies, MDM solutions, wearables or RFID technologies: Barcotec gives you the decisive edge when it comes to digital data capture. In all areas: From the initial idea to the finished solution in retail, logistics, production, warehousing & more. BARCOTEC is a long-standing development partner of RealWear and is active as a channel partner throughout Europe.

Praxiseinsatz von Remote Maintenance Assistance mit der HMT‑1 Datenbrille